What Is Polymer Light Stabilizers (HALS) And How Does It work?

What Is Light Stabilizers (HALS)?

(definition of light stabilizer)

One main category of light stabilizers consists of what are known as Hindered Amine Light Stabilizers (abbreviated as HALS). They are derivatives of 2,2,6,6-tetramethyl piperidine and are extremely efficient stabilizers against light-induced degradation of most polymers.

HALS which are efficient scavengers and function by inhibiting degradation of polymers that have already formed free radicals, they do not absorb UV radiation, but act to inhibit degradation of the polymer .They slow down the photochemically initiated degradation reactions, to some extent in a similar way to antioxidants. Mechanism different of antioxidant and HALS is HALS reaction is cyclic while antioxidant is not.

Commercially, Hindered Amine Light Stabilizers are now the single most important light stabilizers, followed by benzophenones and benzotriazoles.

Synonyms of Light Stabilizer

- Hindered Amine Light Stabilizers (abbreviated as HALS)

- light stabilizer additive

- ultraviolet light absorber

How Does Light Stabilizers (HALS) Work?

(mechanism of light stabilizers)

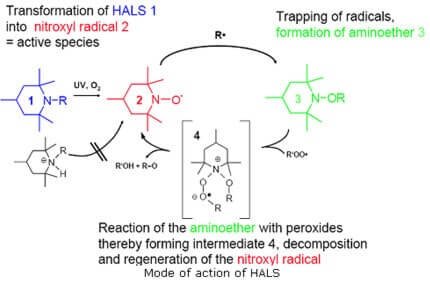

The mechanism is not fully understood. Hydroperoxide decomposition and free radical scavenging certainly play a part, as also does the regeneration of HALSs, where UV absorbers are frequently consumed as a result of their operation. There are several theories for how this works – possibly by energy transfer, free radical termination(as photo below), or peroxide decomposition. Significant stabilization is achieved at relatively low concentrations and it appears that the HALS is actually regenerated by the stabilization process, rather than consumed by it. Theory suggests that the hindered amine oxidizes to form amine-ether, which is a non-radical species.

The effectiveness of HALS systems does not depend on the thickness of the plastics product and they are therefore particularly useful for protection of surface layers and in thin sections. Agents are of low or high molecular weight. Polymeric HALSs offer superior compatibility, low volatility, excellent resistance to extraction, and contribute to heat stability. Combination of two high molecular weight grades gives a good balance of properties in greenhouse film, which is the main use of HALSs in LDPE film.