Laser Engraving Additive BX Laser 8208

Principle of Laser Engraving

A pulsed laser beam of high energy is generated by laser generators. Laser Engraving additives make the light convert into heat energy when the beam acting on the materials is marked. At the same time, their surface is melted, discolored or even gasified, thereby forming a mark. Laser engraving is also known as laser marking, laser carving.

Features of Laser Engraving Additive

- Non-contact processing;

- High precision, fast, high legibility, reliability;

- Forming High-resolution marks;

- Environment-friendly;

- Easy to use, strong security features;

- Strong traceability of products;

- High-speed automatic processing can be achieved;

- The overall production cost of individual parts is far less than that of printing traditional inks.

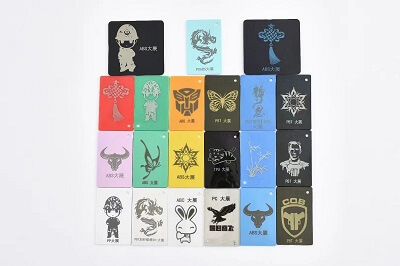

BX Laser 8208 Function

BX Laser 8208 is a necessary additive for plastics, elastomers, and rubbers, which cannot be marked or weakly marked by lasers. The marks produced by BX Laser 8208D are always clear, good, and durable, and these marks cannot be gradually faded away by physical or chemical actions. Used to replace MERCK Iriotec 8208 using our own laser engraving pigment powder. BX Laser engraving additive both available in powder and masterbatch form. Replace Merck Iriotec 8825 & 8208.

Application

BX Laser 8208 is suitable to apply to mark the dark color on the light-colored plastics, elastomers, and rubbers including PP、PE、ABS、PA6、PA66、PS、PBT、PET、POM、SEBS、TPU、TPE, and so on.

Features

- The color of plastics, elastomers, and rubbers does not alter obviously after adding BX Laser 8208

- A high precision Engraving can be achieved, such as a photo level.

Laser Engraving Systems

Systems of the wavelength at 355-1064nm can be used. YAG and fiber laser Engraving systems (355-1064nm) are strongly recommended.

Technical Data of BX Laser 8208

| Parameters | Typical values | Test methods |

| Form | Granule | By Visual |

| Color | Light gray | By Visual |

| Density (g/cm3) | 1.70±0.01 | ISO 1183-1:2004 |

| Suitable laser wavelength (nm) | 355-1064 | Internal test methods |

| Package Size (kg) | 25.0 | — |

Processing

- BX Laser 8208 is recommended to compound with the target materials using extruders. Processing parameters of the target materials remain unchanged during extrusion granulation. Then blow molding, injection molding, extrusion or other technology can be used to produce plastic parts.

- The plastic parts can be directly produced by injection molding, after a simple dry blend of BX Laser 8208 and the target materials.

- During extrusion granulation and direct injection molding, BX Laser 8208 can be used together with color master batch, dyes, and pigments of white, yellow (light), blue(light), red(light), gray, etc.

Dosage

In general, 1.0-2.0 wt% is always recommended.

Toxicity

BX Laser 8208 is no danger to humans, and it’s environment-friendly.

Package and Storage

- BX Laser 8208 is packaged by a plastic box or a carton lined with a PE bag;

- BX Laser 8208 is non-dangerous good;

- Please store in dry and ventilated conditions;

- Waterproof and moisture-proof;

- Avoid sun exposure;

- Please seal the unused portion of BX Laser 8208;

- Please use up within 24 months.

TDS and MSDS

BX Laser 8208 TDS Laser Engraving Baoxu chemical

Sample and Inquiry

Please contact our online sales or mail at info@additivesforpolymer.com for a sample and general inquiries.