Baoxu Fluorescent Pigment & Dye

BXColor Fluorescent Colorants are essentially fluorescent dyes and pigments dissolved in polymer application. The typical polymer matrices include different amino resins, polyesters, copolymers of ester and amide, polyamide, and acrylic resin. They are in powder forms with various particle sizes, or powders dispersed in water/solvent or vehicle. Some of our products are formaldehyde-free.

Each of BXColor® Fluorescent Colorants has unique sets of properties and functions. Some of them have multiple functions and applications, while others are designed with particular functionalities for specialized applications. It is critical that end-users provide application information in as much detail as possible for us to come up with the best possible recommendations.

BXColor Fluorescent Pigment Dye Series

BXColor Fluorescent Pigment Dye Series

| Product series | Features | Application |

| (table) | BXColor® vs Competition Brand | |

| (table) | Recommended Applications | |

| FA Amino resin | Microspheres; solvent resistant; thermoset | Inks, Paints & Coatings |

| FB | Microspheres; solvent resistant; thermoset | Inks, Paints & Coatings, EVA, Rubber |

| FC Amino resin | Microspheres; solvent resistant; thermoset | Inks, Paints & Coatings |

| FD Amino resin | Microspheres; solvent resistant; thermoset | Inks, Paints & Coatings |

| FE Amino resin | water and weak solvent; thermoplastic | Inks, Paints & Coatings |

| FF Amino resin | solvent resistant; thermoset | Inks, Paints & Coatings |

| FG Polyamide-ester resin | non-formaldehyde; thermoplastic | Crayons, Modeling Clay & textiles |

| FH Polyester resin | non-formaldehyde; water-soluble fluorescent toners | Flexo & gravure inks; highlighter inks for felt tip markers |

| FI Amino resin | solvent-soluble fluorescent toners | Flexo, gravure and UV-cure inks; |

| FG Polyester resin | Non-formaldehyde; thermoplastic | Moldings |

| FK Polyamide-ester resin | non-formaldehyde; thermoplastic | low-temperature moldings |

| FL Polyamide-ester resin | non-formaldehyde; thermoplastic | high-temperature plastics |

| FM Polyamide-ester resin | non-formaldehyde; thermoplastic | high-temperature plastics |

| FN Amino resin | Microspheres; Anti-Plate out; bleed-resistant; | Extruded (Masterbatch) & molded polyolefins; PVC coating & molding |

| FO Amino resin in modified alkyd resin as vehicle | Fluorescent ink base with ultra fine, thermoplastic fluorescent pigments dispersed in a modified alkyd vehicle. | Offset printing and letterpress printing |

BXCOLOR® vs Brand Fluorescent Pigment Dye

| BXCOLOR® | Radiant Color | DayGlo | Sun Chem | Sinloihi | Sterling | Swada Fiesta | |

| Paint Inks | FA/FC Solvent-Resisting | MC | |||||

| Paint Inks | FB Solvent-Resisting | 210 | RTS | ||||

| Paint Inks | FD Solvent-Resisting | ||||||

| Paint Inks | FE Waterborne systems | R5, R6 | A, AX | B3500 B2800 | FZ2000 FZ3500 FZ5000 FZ6000 | 610 710 | A/D, E, FEX |

| Paint Inks | FF Solvent- Resisting | P7 | T GT | SR TS | FA200 FR50 FA40 | 810 850 | T FTX |

| Textile | FG Non-Formaldehyde | T1 | |||||

| Marker Inks | FH Non-Formaldehyde Water-soluble Toner | ST | 450 | ||||

| Inks | FI Solvent-Soluble Toner | GF | HM HMS | HVT | FM100 | 410 | EBT |

| Plastics | FG Non-Formaldehyde | K6 | |||||

| Plastics | FK Non-Formaldehyde | K8 | LMP | ||||

| Plastics High- temp | FL Non-Formaldehyde | K7 | Z, | 911 915 920 | HMP | ||

| Plastics | FM Non-Formaldehyde | K2000 | ZQ | Vizitek | SB10 | 510 520 | XSP |

| Plastics | FN Anti-plateout | MP AFC | FX300 | RTS | |||

| Inks | FO | VF | SFB | 325 | BPC |

Recommended Applications of BXCOLOR Fluorescent Pigment Dye

| Product Series | FE | FF | FA/FC FB/FD | FH | FI | FG FK | FL FM | FG GL | FG | FO | |

| Modeling Clay/Crayons | ◆ | ▽ | ▽ | ◆ | |||||||

| Flexo Ink | Water | ▽ | ▽ | ◆ | |||||||

| Solvent | ◆ | ◆ | ◆ | ▽ | ◆ | ||||||

| UV | ◆ | ||||||||||

| Gravure Ink | Aliphatic | ◆ | ▽ | ▽ | |||||||

| Aromatic | ▽ | ▽ | ▽ | ||||||||

| Alcohol/Ester | ◆ | ◆ | ◆ | ▽ | |||||||

| Water | ◆ | ▽ | ◆ | ||||||||

| Paper Coating | ◆ | ▽ | ▽ | ||||||||

| Paint | Water Based | ◆ | ▽ | ||||||||

| Solvent Based | ◆ | ◆ | ▽ | ||||||||

| Aerosol | ◆ | ◆ | ▽ | ||||||||

| Powder Coating | ▽ | ▽ | ▽ | ▽ | ▽ | ||||||

| Plastisol | Coatings | ◆ | ◆ | ▽ | |||||||

| Molded Parts | ◆ | ◆ | ▽ | ||||||||

| Screen Ink | Plastisol | ▽ | ◆ | ◆ | |||||||

| Water/Aliphastic | ◆ | ||||||||||

| OtherSolvents | ◆ | ◆ | |||||||||

| UV | |||||||||||

| Textile | Dying | ▽ | ▽ | ||||||||

| Printing | ▽ | ▽ | |||||||||

| Plastics | Liquid-Color Masterbatch | ▽ | ◆ | ◆ | |||||||

| Vinyl | ▽ | ◆ | ◆ | ||||||||

| < 240°C | ▽ | ◆ | ▽ | ◆ | |||||||

| 185-290°C | ◆ | ◆ | |||||||||

◆ recommended; ▽ may be used

BXCOLOR® FA SERIES Fluorescent Pigment Dye

Solvent and bleed resistant Fluorescent Pigments; Thermoset & Microspherical

| Recommended Applications: | Bleed Resistant Vinyl Plastisols, Specialty Coatings/Inks, Solvent Sensitive Systems, and Crayons | ||||||||||

| Highlight of Properties: | Thermoset, narrow-distributed microspherical particles render properties of good resistance to solvent and bleed, and excellent light scattering and opacity, dispersibility, tinting strength, and broad compatibility. | ||||||||||

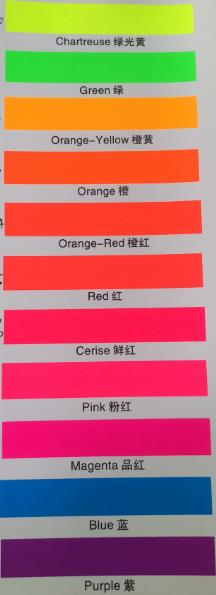

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple | ||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in an amino resin | ||||||||||

| Physical properties: | |||||||||||

| Shape and state: | Solid micron-sized spherical particles | ||||||||||

| pH: | 3.8~ 6 (5% dispersion in water) | ||||||||||

| *Moisture*: | < 4% (2 grams under 140C for 0.5 hours) | ||||||||||

| Specific Gravity: | 1.3 (20℃) | ||||||||||

| Solvent Resistance: | Not soluble in most solvent systems. (Solubility is tested in a 40C water bath for 30 minutes. Following the solubility test, the appearance of the supernatant is observed and marked for bleed scales.) | ||||||||||

| Bleed Resistance: |

Bleed scales: 0 – negligible; 1 – slight; 2 – moderate; 3 – considerable | ||||||||||

| *Particle Size* (Microscope): | Maximum 10 mm; Average <5 mm | ||||||||||

| Softening Point: | Thermoset; no softening point. But observed color changes at ~260℃ | ||||||||||

| Decomposition Point: | > 300℃; Maximum Processing Temperature: 260℃ | ||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns and placed in standard light box equipped with UV and D65 light source. | ||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FA pigments have an indefinite shelf life. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | ||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FA-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | ||||||||||

| Note: | 1. Items marked with * are standard QC items taken on batch bases. 2. Prepared by: HJW; Revised: LS 2011-12-5, HJW 202-3-6 | ||||||||||

BXCOLOR® FB SERIES Fluorescent Pigment Dye

| PRODUCT: | Better Solvent and bleed Resistance; Excellent Plate-out resistance; Thermoset Microspherical Fluorescent pigments | ||||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, | ||||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in an amino resin | ||||||||||||

| Highlight of Properties: | Thermoset, narrow-distributed microspherical particles render properties of much-improved resistance to solvent and bleed (color migration), excellent resistance to plate-out; excellent light scattering and opacity, dispersability, tinting strength, and broad compatibility. Higher color strength than GQ. | ||||||||||||

| Recommended Applicatoin | EVA foam, PVC rubber, Rubber, Plastics, Bleed resistant Vinyl Plastisols, Specialty Coatings/Inks, Sensitive Systems | ||||||||||||

| Physical properties: | |||||||||||||

| Shape and state: | Solid micron-sized spherical particles | *Particle Size* | Average 2 – 4 mm | ||||||||||

| pH: | 3 ~ 8 (5% dispersion in water) | Specific Gravity: | 1.3 (20℃) | ||||||||||

| *Moisture*: | < 4% (2 gram under 140℃ for 0.5 hours) | ||||||||||||

| Softening Point: | Thermoset, not detectable | Decomposition: | >220℃ | ||||||||||

| Light Fastness: | Good in indoor applications; Limited with UV exposure or direct sunshine. | ||||||||||||

| Solvent Resistance: | Not soluble in most solvent systems. Swelling observed in some polar systems such as MEK, ethyl alcohol, 2-propanol. Solubility is tested in a 40C water bath for 30 minutes. Following the solubility test, appearance of the supernatant is observed and marked for bleed scales. | ||||||||||||

| Bleed Resistance: |

Bleed scales: 0 – negligible; 1 – slight; 2 – moderate; 3 – considerable | ||||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns and placed in standard light box equipped with UV and D65 light source. | ||||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FB pigments have an indefinite shelf life in theory. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | ||||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FB-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | ||||||||||||

| regulation: | EN71.3 (Heavy metal) compliant; RoHS compliant | ||||||||||||

| Note: | Items marked with * are standard QC items taken on batch bases. | ||||||||||||

BXCOLOR® FC SERIES

| PRODUCT: | Thermoset Microspherical Fluorescent Pigments | ||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, | ||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in an amino resin | ||||||||||

| Highlight of Properties: | Thermoset, narrow-distributed microspherical particles render properties of much-improved resistance to solvent and bleed (color migration), and excellent light scattering and opacity, dispersability, tinting strength, and broad compatibility. | ||||||||||

| Recommended Applicatoin | Bleed Resistant Vinyl Plastisols, Specialty Coatings/Inks, Solvent Sensitive Systems, and Crayons | ||||||||||

| Physical properties: | |||||||||||

| Shape and state: | Solid micron-sized spherical particles | ||||||||||

| pH: | 3.8~ 6 (5% dispersion in water) | ||||||||||

| *Moisture*: | < 4% (2 grams under 140℃ for 0.5 hours) | ||||||||||

| Specific Gravity: | 1.3 (20℃) | ||||||||||

| Solvent Resistance: | Not soluble in most solvent systems. Swelling observed in some polar systems such as MEK, ethyl alcohol, 2-propanol. Solubility is tested in a 40℃ water bath for 30 minutes. Following the solubility test, appearance of the supernatant is observed and marked for bleed scales. | ||||||||||

| Bleed Resistance: |

Bleed scales: 0 – negligible; 1 – slight; 2 – moderate; 3 – considerable | ||||||||||

| *Particle Size* (Microscope): | Maximum 10 mm | ||||||||||

| *Particle Size* | Average <5 mm | ||||||||||

| Softening Point: | Thermoset, not detectable | ||||||||||

| Decomposition Point: | > 300℃ | ||||||||||

| Maximum Processing Temperature: | 260℃ | ||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns and placed in standard light box equipped with UV and D65 light source. | ||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FC pigments have an indefinite shelf life in theory. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | ||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FC-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | ||||||||||

| Note: | 1. Items marked with * are standard QC items taken on batch bases. 2. Prepared by: HJW; Revised by: ZH 2011-12-5 | ||||||||||

BXCOLOR® FD SERIES Fluorescent Pigment Dye

| PRODUCT: | Better Solvent & Bleed Resisting Fluorescent Pigments; Thermoset Microspherical | |||||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, | |||||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in an amino resin | |||||||||||||

| Highlight of Properties: | Thermoset, narrow-distributed microspherical particles render properties of much-improved resistance to solvent and bleed (color migration), and excellent light scattering and opacity, dispersability, tinting strength, and broad compatibility. | |||||||||||||

| Recommended Applications: | PVC rubber, Bleed Resistant Vinyl Plastisols, Specialty Coatings/Inks, Solvent Sensitive Systems, Rubber, Paper Coatings, Textile Printing Inks, etc. | |||||||||||||

| Physical properties: | ||||||||||||||

| Shape and state: | Solid micron-sized spherical particles | *Particle Size* | Average <3 mm | |||||||||||

| *pH*: | 6 ~ 7 (5% dispersion in water) | Specific Gravity: | 1.3 (20℃) | |||||||||||

| *Moisture*: | < 4% (2 gram under 140℃ for 0.5 hours) | |||||||||||||

| Softening Point: | Thermoset, not detectable | Heat resistance: | < 190℃ | |||||||||||

| Light Fastness: | Good in indoor applications; Limited with UV exposure or direct sunshine. | |||||||||||||

| Solvent Resistance: | Not soluble in most solvent systems. Swelling is observed in some polar systems such as MEK, ethyl alcohol, 2-propanol. Solubility is tested in a 40C water bath for 30 minutes. Following the solubility test, the appearance of the supernatant is observed and marked for bleed scales. | |||||||||||||

| Bleed Resistance: |

Bleed scales: 0 – negligible; 1 – slight; 2 – moderate; 3 – considerable | |||||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns and placed in standard light box equipped with UV and D65 light source. | |||||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FD pigments have an indefinite shelf life in theory. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | |||||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FD-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | |||||||||||||

| regulation: | EN71.3 (Heavy metal) compliant; RoHS compliant | |||||||||||||

| Note: | 1. Items marked with * are standard QC items taken on batch bases. 2. Prepared by: YSP 2015-2-26; Revised by: ZXQ/ZH 2015-2-27; Translated & revised by: HJW 2015-3-16 | |||||||||||||

BXCOLOR® FE-SERIES Fluorescent Pigment Dye

Thermoplastic Fluorescent Pigments; for waterborne and non-polar solvents

| Recommended Applications: | For a wide range of applications where resistance to strong solvents is not needed. Perform well in a system based on aliphatic and some aromatic hydrocarbons. Also usable in water systems where prolonged shelf life is not required. Recommended for such applications as paper coatings, vinyl coated fabric, A-type gravure inks, paints, screen inks, vinyl plastisols, plastics, modeling clay, and crayons. | ||||||||||||||

| Highlight of Properties: | Thermoplastic, tinting strength, and broad compatibility. | ||||||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple | ||||||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in an amino resin | ||||||||||||||

| Physical properties: | |||||||||||||||

| Shape and state: | Solid irregular shaped particles | ||||||||||||||

| Oil Absorption: | 50-60g/100g | ||||||||||||||

| Moisture: | < 2% (2 gram under 140C for 0.5 hours) | ||||||||||||||

| Specific Gravity: | 1.3 (20℃) | ||||||||||||||

| Solvent Resistance: |

Solubility scales: 1- Entirely Soluble; 2- Soluble; 3-Slight 4-Negligible; 5-None; NOTE: The above information is offered as a reference only. | ||||||||||||||

| *Particle Size* (Microscope): | Maximum 10 mm; Average <5 mm | ||||||||||||||

| *Softening Point*: | 80~110℃ | ||||||||||||||

| Decomposition Point: | > 300℃ | ||||||||||||||

| Maximum Processing Temperature: | 190℃ | ||||||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns or plastic chips and placed in standard light box containing UV and D65. | ||||||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FE pigments have an indefinite shelf life in theory. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | ||||||||||||||

| TOXICITY: | Tests conducted through independent laboratories have found BXCOLOR® FE-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | ||||||||||||||

| Note: | 1. Items marked with * are standard QC items taken on batch bases. 2. Prepared by: HJW; Revised by HJW 2012-3-6 | ||||||||||||||

BXCOLOR® FF-SERIES Fluorescent Pigment Dye

Solvent-resistant, Thermoset Fluorescent Pigments

| Recommended Applications: | Coatings and Inks where strong solvents are applied; other solvent-sensitive systems | ||||||||||||

| Highlight of Properties: | Thermoset, narrow distributed particles; Excellent resistance to solvent and bleed; Good tinting strength, and broad compatibility. | ||||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple | ||||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in a thermoset amino resin | ||||||||||||

| Physical properties: | |||||||||||||

| Shape and state: | Solid irregular shaped particles | ||||||||||||

| pH: | 6~ 7 (5% dispersion in water at 20℃) | ||||||||||||

| *Moisture*: | < 4% (2 gram under 140℃ for 0.5 hours) | ||||||||||||

| Specific Gravity: | 1.3 (20℃) | ||||||||||||

| Solvent Resistance: | Not soluble in most solvent systems and water. Slightly soluble in polar solvent systems such as MEK, 2-propanol, ethyl acetate, and toluene. Solubility is tested in a 40C water bath for 30 minutes, following which the appearance of the supernatant is observed and marked for bleed scales. | ||||||||||||

| Bleed Resistance: |

Bleed scales: 0 – negligible; 1 – slight; 2 – moderate; 3 – considerable | ||||||||||||

| *Particle Size* (Microscope): | Maximum 10 mm | ||||||||||||

| *Particle Size* | Average <5 mm | ||||||||||||

| Softening Point: | Thermoset; no softening point. But observed color changes at ~190℃ | ||||||||||||

| Decomposition Point: | > 300℃ | ||||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side drawdowns and placed in standard light box equipped with UV and D65 light source. | ||||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FF pigments have an indefinite shelf life in theory. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | ||||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FF-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | ||||||||||||

| Note: | 1. Items marked with * are standard QC items taken on batch bases. 2. Prepared by: HJW; Revised by: HJW 2012-3-6 | ||||||||||||

BXCOLOR® FG SERIES Fluorescent Pigment Dye

Formaldehyde-Free Thermoplastic Fluorescent Pigments

| Recommended Applications: | Aqueous and Non- aqueous systems; Flexo and gravure inks; Screen and textile inks; Aerosol, brush-on, and spray paints; Coatings; Colorants for crayons; Plastisols | |||||||||||||||||||||||||||

| Highlight of Properties: | Formaldehyde-free, thermoplastic, heat stability up to 300C, good tinting strength, broad compatibility, fade-resistant | |||||||||||||||||||||||||||

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple | |||||||||||||||||||||||||||

| Chemical nature: | A solid solution of fluorescent dyes in a polyamide resin | |||||||||||||||||||||||||||

| Physical properties: | ||||||||||||||||||||||||||||

| Shape and state: | Solid irregularly shaped particles | |||||||||||||||||||||||||||

| pH: | N/A | |||||||||||||||||||||||||||

| Moisture: | < 2% (2 gram under 140℃ for 0.5 hours) | |||||||||||||||||||||||||||

| Gravity: | Specific Gravity 1.3 (20℃); Bulk ~ 0.5 | |||||||||||||||||||||||||||

| *Particle Size* (Microscope): | Maximum 10 mm; Average <5 mm | |||||||||||||||||||||||||||

| *Softening Point*: | 140-160℃ | |||||||||||||||||||||||||||

| Decomposition Point: | > 300℃ | |||||||||||||||||||||||||||

| Solubility and bleed Resistance |

A – Insoluble 0 – None B – Slightly Soluble 1 – Slight C – Partly Soluble 2 – Moderate D – Soluble 3 – Considerable | |||||||||||||||||||||||||||

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing plastic chips and placed in standard light box containing UV and D65. | |||||||||||||||||||||||||||

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FG pigments have an indefinite shelf life. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | |||||||||||||||||||||||||||

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FG-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | |||||||||||||||||||||||||||

| Note: | Items marked with * are standard QC items taken on batch bases. | |||||||||||||||||||||||||||

BXCOLOR® FH SERIES Fluorescent Pigment Dye

NON-FORMALDEHYDE WATER-SOLUBLE FLUORESCENT TONERS

Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue

TARGETED APPLICATIONS

Water-based flexographic and gravure inks; Highlighter inks for felt tip markers

SUMMARY OF PROPERTIES

Thermoplastic, polyester-based, dry granular powders, formaldehyde-free

Water-soluble (with a small amount of ammonia and alcohol),

Excellent film-forming properties with high color strength and high gloss.

Superior lightfastness compared to most solvent-based counterparts,

Excellent transparency

STORAGE In a sealed container, away from heat, humidity, and direct sunlight. Stay away from electrostatic charges, and ignition sources. Otherwise, tend to solidify and form lumps, which, upon crashing and milling, can also be used. Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchase.

TOXICITY Formaldehyde-free; complies with currently available international standards on heavy metal concentrations. MSFE is available upon request.

| Typical 30% Solids JM Ink Formula (by weight) | Typical FM Water-Based Felt Tip Marker Ink | |||

| Water | 25 | Ink (30% solid) | 40 | |

| Isopropanol | 16 | Ethylene Glycol or PEG 200 | 30 | |

| Ammonium Hydroxide (9%) | 4 | Water | 30 | |

| FH (Dry) | 30 | Total | 100 | |

| Water | 25 | Mix well and adjust solvents to the desired rate of drying | ||

| Total | 100 | |||

BXCOLOR® FI SERIES Fluorescent Pigment Dye

SOLVENT-SOLUBLE FLUORESCENT TONERS FOR PRINTING INKS

Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue

RECOMMENDED APPLICATIONS

Solvent-based flexographic and gravure printing inks, and UV-cure inks. Can be applied on gift wraps, label stocks, tissue coating, corrugated containers, flexible packaging papers, plastics, glass, metal, wood, films, foils, and other specialty coatings. For indoor applications.

SUMMARY OF PROPERTIES

Form: dry granular powder,

Nature: amino resin-based, thermoplastic

Softening Point: 60-70℃

Solubility:

Excellent in propyl acetate, isopropyl acetate, ethyl acetate, 2-nitropropane, Diethylene glycol, dipropylene glycol;

Good in Monochlorobenzene, Orthodichlorobenzene;

Good in Ethylene glycol monoethyl ether, Ethanol, Isopropanol, and Propylene glycol when used as cosolvents.

Compatibility: Compatible with most flexographic ink binders, including nitrocellulose, ethyl cellulose, cellulose acetate butyrate, other alcohol-soluble butyrate, acrylics, ketone resins, and maleic resins. Also compatible with low percentage (around 2%) waxes and/or polyethylene dispersion additives. More compatible modifiers have to be applied to improve the limited compatibility with Polyamide resins.

STORAGE AND SHELF LIFE: When stored in a sealed container, away from heat, humidity, and direct sunlight, BXCOLOR® FI have an indefinite shelf life. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources.

EM Series Starting Point Formulations

Formulation A: Unmodified Gloss Solution

| Ingredients | EM soluble toner | Ethyl alcohol | Ethyl acetate | Total | Viscosity (cps); |

| % by Wt | 45.0 | 33.0 | 22.0 | 100 | 15 ~ 30 |

Formulation B: Nitrocellulose Modification

| Ingredients | EM Toner | Nitrocellulose | Plasticizer | Ethyl alcohol | Ethyl acetate | Total | Viscosity (cps) |

| % by Wt | 36.3 | 4.2 | 2.1 | 37.3 | 20.1 | 100.0 | 105~130 |

Formulation C: Polyamide Modification

| Ingredients | EM Toner | Nitrocellulose | Alcohol-soluble polyamide resin | Ethyl alcohol | Ethyl acetate | Total | Viscosity (cps) |

| % by Wt | 35.0 | 3.5 | 3.5 | 40.0 | 18.0 | 100.0 | 70~120 |

Formulation D: Alcohol-Souble Butyrate Modification

| Ingredients | EM Toner | Alcohol-soluble butyrate | Ethyl alcohol | Ethyl acetate | Total | Viscosity (cps) |

| % by Wt | 34.0 | 6.0 | 39.0 | 21.0 | 100.0 | 105~180 |

Formulation E: UV-Cure Concentrate

| Ingredients | EM Toner | Ethoxylated Trimethylol Propane triacrylate (TMPTA) | Total | Viscosity (cps) |

| % by Wt | 35.0 | 65.0 | 100.0 | 1000~1600 |

1. Ethyl acetate may be replaced with less volatile isopropyl acetate or normal propyl acetate (active retarder solvents) to improve leveling properties or to slow the drying rate

2. Viscosity is measured by Brookfield, No. 1 spindle

3. Use denatured ethyl alcohol

Flexographic inks prepared with BXCOLOR® FI can be formulated with better cellophane tape-resistant adhesion, crinkle resistance, block resistance and abrasion resistance. Reference formulations are available upon request.

BXCOLOR® FG SERIES Fluorescent Pigment Dye

Formaldehyde-Free Thermoplastic Fluorescent Pigments

| Recommended Applications: | Plastics. May be used in injection, rotational and blow molding, extruded film and sheet, blown and calendared film, vacuum forming, casting, etc. | |

| Highlight of Properties: | Formaldehyde-free, thermoplastic, low melt point, melt-in, heat stability up to 240C, good tinting strength, broad compatibility, fade-resistant, minimal color shifts over a wide processing temperature range.. | |

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue | |

| Chemical nature: | A solid solution of fluorescent dyes in a polyester resin | |

| Physical properties: | ||

| Shape and state: | Solid irregularly shaped particles | |

| Moisture: | < 2% (2 gram under 140C for 0.5 hours) | |

| Specific Gravity: | 1.3 (20℃) | |

| *Particle Size* (Microscope): | Maximum 100 mm; Average <60 mm | |

| *Softening Point*: | 70-80℃ | Decomposition Point: > 260℃ |

| Maximum Processing Temperature: | 240℃ | |

| Application in Plastic Systems: | JC100 series has been successfully applied in HDPE, LDPE, PP, and PS systems with minimum adjustment to the processing conditions. In theory, it should be also applicable in many other plastic systems, but we suggest that the end-users perform thorough test of their own to determine the suitability and adjust the formulation and processing parameters accordingly. | |

| Lightfastness: | The degree of colorfastness of FG series fluorescent pigments vary depending upon many factors such as the specific properties and dimensions of plastic systems, pigment loading, the presence of a protective overcoat or agent and the light source. It is reported that an improvement of 10 to 30% in exterior light stability results from the incorporation of 0.5 to 1.0% of a benzotriazole or benzophenone-type UV screen. It is essential to select an UV screen that is compatible with the plastic in which it is to be incorporated. | |

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing plastic chips and placed in standard light box containing UV and D65. | |

| Storage: | Indefinite shelf life under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates. Upon exposure to heat and humidity, FG pigment tends to form lumps that need to be crashed prior to use. Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchase. Stay away from electrostatic charges, and ignition sources. | |

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FG-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. | |

| Note: | Items marked with * are standard QC items taken on batch bases. | |

BXCOLOR® FK SERIES Fluorescent Pigment Dye

Formaldehyde-Free Thermoplastic Fluorescent Pigments

| Recommended Applications | Plastics. May be used in injection, rotational and blow molding, extruded film and sheet, blown and calendared film, vacuum forming, casting, etc. | |

| Highlight of Properties: | Formaldehyde-free, thermoplastic, low melt point, melt-in, heat stability up to 220C, good tinting strength, broad compatibility, fade-resistant, minimal color shifts over a wide processing temperature range.. | |

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple | |

| Chemical nature: | A solid solution of fluorescent dyes in a polyester resin | |

| Physical properties: | ||

| Shape and state: | Solid irregularly shaped particles | |

| Moisture: | < 2% (2 gram under 140C for 0.5 hours) | |

| Specific Gravity: | 1.3 (20℃) | |

| Application in Plastic Systems: | FK series has been successfully applied in HDPE, LDPE, PP, and PS systems with minimum adjustment to the processing conditions. In theory, it should be also applicable in many other plastic systems, but we suggest that the end-users perform thorough test of their own to determine the suitability and adjust the formulation and processing parameters accordingly. | |

| Lightfastness: | The degree of colorfastness of FK series fluorescent pigments vary depending upon many factors such as the specific properties and dimensions of plastic systems, pigment loading, presence of a protective overcoat or agent and the light source. It is reported that an improvement of 10 to 30% in exterior light stability results from the incorporation of 0.5 to 1.0% of a benzotriazole or benzophenone-type UV screen. It is essential to select a UV screen that is compatible with the plastic in which it is to be incorporated. | |

| *Particle Size* (Microscope): | Maximum 100 mm; Average <60 mm | |

| *Softening Point*: | 70-90℃ | Decomposition Point: > 240℃ |

| Maximum Processing Temperature: | 220℃ | |

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing plastic chips and placed in standard light box containing UV and D65. | |

| Storage: | Indefinite shelf life under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates. Upon exposure to heat and humidity, FK pigment tends to form lumps that need to be crashed prior to use. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. | |

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FK-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling metho FE are essential in the use of all products whether or not they are determined to be hazardous. | |

| Note: | Items marked with * are standard QC items taken on batch bases. | |

BXCOLOR® FL SERIES Fluorescent Pigment Dye

Formaldehyde-Free Thermoplastic Fluorescent Pigments

| Recommended Applications: | Plastics. Can be used for preparing extruded color compounds and liquid color dispersions for use in injection, rotational and blow molding, extruded film and sheet, blown and calendared film, vacuum forming, casting, etc. |

| Highlight of Properties: | Formaldehyde-free, thermoplastic, good resistance to plate-out, melt-in, heat stability up to 300C, good tinting strength, broad compatibility, fade-resistant, minimal color shifts over a wide processing temperature range.. |

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple |

| Chemical nature: | A solid solution of fluorescent dyes in a polyamide resin |

| Physical properties: | |

| Shape and state: | Solid irregularly shaped particles |

| Moisture: | < 2% (2 gram under 140C for 0.5 hours) |

| Specific Gravity: | 1.3 (20℃) |

| Application in Plastic Systems: | FL series has been successfully applied in HDPE, LDPE, PP, and PS systems with minimum adjustment to the processing conditions. In theory, it should be also applicable in many other plastic systems, but we suggest that the end-users perform thorough tests of their own to determine the suitability and adjust the formulation and processing parameters accordingly. |

| Lightfastness: | The degree of colorfastness of JC-200 series fluorescent pigments vary depending upon many factors such as the specific properties and dimensions of plastic systems, pigment loading, presence of a protective overcoat or agent and the light source. It is reported that an improvement of 10 to 30% in exterior light stability results from the incorporation of 0.5 to 1.0% of a benzotriazole or benzophenone-type UV screen. It is essential to select an UV screen that is compatible with the plastic in which it is to be incorporated. |

| *Particle Size* (Microscope): | Maximum 100 mm; Average <60 mm |

| *Softening Point*: | 140-160℃ |

| Decomposition Point: | > 300℃ Maximum Processing Temperature: 290℃ |

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing plastic chips and placed in a standard light box containing UV and D65. |

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FL pigments have an indefinite shelf life. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. |

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FL-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. |

| Note: | Items marked with * are standard QC items taken on batch bases. |

BXCOLOR® FM SERIES Fluorescent Pigment Dye

Formaldehyde-Free Thermoplastic Fluorescent Pigments

| Recommended Applications: | Plastics. May be used in injection, rotational and blow molding, extruded film and sheet, blown and calendared film, vacuum forming, casting, etc. |

| Highlight of Properties: | Formaldehyde-free, thermoplastic, low melt point, melt-in, heat stability up to 260C, good tinting strength, broad compatibility, fade-resistant, minimal color shifts over a wide processing temperature range.. |

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple |

| Chemical nature: | A solid solution of fluorescent dyes in a polyamide resin |

| Physical properties: | |

| Shape and state: | Solid irregularly shaped particles |

| Moisture: | < 2% (2 gram under 140C for 0.5 hours) |

| Specific Gravity: | 1.3 (20℃) |

| Application in Plastic Systems: | FM series has been successfully applied in HDPE, LDPE, PP, and PS systems with minimum adjustment to the processing conditions. In theory, it should be also applicable in many other plastic systems, but we suggest that the end-users perform thorough test of their own to determine the suitability and adjust the formulation and processing parameters accordingly. |

| Lightfastness: | The degree of colorfastness of FM series fluorescent pigments vary depending upon many factors such as the specific properties and dimensions of plastic systems, pigment loading, the presence of a protective overcoat or agent and the light source. It is reported that an improvement of 10 to 30% in exterior light stability results from the incorporation of 0.5 to 1.0% of a benzotriazole or benzophenone-type UV screen. It is essential to select a UV screen that is compatible with the plastic in which it is to be incorporated. |

| *Particle Size* (Microscope): | Maximum 100 mm ; Average <60 mm |

| *Softening Point*: | 105-115℃ |

| Decomposition Point: | > 290℃; Maximum Processing Temperature: 280℃ |

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing plastic chips and placed in a standard light box containing UV and D65. |

| Storage: | Indefinite shelf life under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates. Upon exposure to heat and humidity, FM pigment tends to form lumps that need to be crashed prior to use. Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchase. Stay away from electrostatic charges, and ignition sources. |

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FM-Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. |

| Note: | Items marked with * are standard QC items taken on batch bases. |

BXCOLOR® FN SERIES Fluorescent Pigment Dye

Anti Plate-out Fluorescent Pigments

| Recommended Applications: | Extruded (Masterbatch) & moulded polyolefin plastics; PVC coating & moulding |

| Highlight of Properties: | Thermoset, narrow-distributed microspherical particles render new properties ever seen before: the best resistance to plate out, and plasticizers, and excellent light scattering and opacity, dispersibility, tinting strength, and broad compatibility. |

| SHADES: | Chartreuse, Green, Orange-Yellow, Orange, Orange-Red, Red, Cerise, Pink, Magenta, Blue, Purple |

| Chemical nature: | A solid solution of fluorescent dyes in a thermoset amino resin |

| Physical properties: | |

| Shape and state: | Solid micron-sized spherical particles |

| pH: | 6~ 8 (5% dispersion in water) |

| *Moisture*: | < 4% (2 gram under 140C for 0.5 hours) |

| Specific Gravity: | 1.3 (20℃) |

| Solvent Resistance: | Not soluble in most solvents and plasticizers. (Solubility is tested in a 40C water bath for 30 minutes. Following the solubility test, the appearance of the supernatant is observed and marked for bleed scales.) |

| Platelet resistance | Minimizes the build-up of plate-out in molded and extruded plastics |

| *Particle Size* (Microscope): | Maximum 10 mm; Average <5 mm |

| Softening Point: | Thermoset; no softening point. But observed color changes at ~270℃ |

| Decomposition Point: | > 300℃ |

| Maximum Processing Temperature: | 260℃

|

| *Color assessment*: | Shade (hue) and strength are compared against an approved standard by trained technicians upon preparing side-by-side plastic chips and placing them in standard light box equipped with UV and D65 light sources. |

| Storage: | Under conditions that are cool, dry, covered, away from direct sunlight and free of airborne contaminates, FN pigments have an indefinite shelf life. But Baoxu Chemical will not assume responsibility for storage time longer than 6 months upon purchasing. Stay away from electrostatic charges, and ignition sources. |

| Toxicity:

| Tests conducted through independent laboratories have found BXCOLOR® FN Series Fluorescent Pigments to be “essentially non-toxic.” MSFE is available upon request. Good industrial hygiene and handling methods are essential in the use of all products whether or not they are determined to be hazardous. |

| Note: | Items marked with * are standard QC items taken on batch bases. |

RECOMMENDED STARTING FORMULAS

| Quickset | Heat set | News | |

| BXCOLOR® JCF FLUSHES | 80.0 | 80.0 | 80.0 |

| Quickset Gel Varnish | 7.0 | ||

| Quickset Gloss Varnish | 5.0 | ||

| Heatset Varnish | 12.0 | 15.0 | |

| Mineral Oil (Magiesol) | 3.0 | 3.0 | 5.0 |

| 6% Manganese Dryer | 0.5 | ||

| 18% Zirconium Dryer | 1.0 | 1.0 | |

| PTFE | 0.5 | 1.0 | |

| Wax | 3.0 | 3.0 | |

| Total | 100 | 100 | 100 |

Technical Specifications of BXCOLOR® Fluorescent Pigment Dye

| Density (g/cm3) | Softening Point | Average Particle Size | Maximum Particle Size | Processing Temperature | Decomposing Temperature (inert gas) | |

| FA | 1.3 | n/a | ~5μm | <10μm | <260℃ | > 280℃ |

| FB | 1.3 | n/a | ~5μm | <10μm | <260℃ | > 280℃ |

| FC | 1.3 | n/a | ~5μm | <10μm | <260℃ | |

| FD | 1.3 | n/a | ~5μm | <10μm | <260℃ | |

| FE | 1.30 | 90-100℃ | ~5μm | <10μm | <190℃ | > 200℃ |

| FF | 1.32 | ~150 ℃ | ~5μm | <10μm | <300℃ | > 280℃ |

| FG | 1.25 | 140-155℃ | ~5μm | <10μm | <300℃ | >300℃ |

| JM | 1.25 | 60-70℃ | ~20μm | ~60μm | <200℃ | > 200℃ |

| EM | 1.26 | 60-70℃ | ~20μm | ~60μm | <200℃ | > 200℃ |

| FK | 1.27 | 80-90℃ | <60μm | <100μm | 135 – 240℃ | > 260℃ |

| FL | 1.27 | 70-80℃ | <60μm | <100μm | 135 – 220℃ | > 250℃ |

| FM | 1.25 | ~110℃ | <60μm | <100μm | 150 – 280℃ | >300℃ |

| FL | 1.25 | 140-155℃ | <60μm | <100μm | 185-290℃ | >300℃ |

| FG | 1.31 | n/a | ~5μm | <10μm | <260℃ | > 280℃ |

Color Selections of BXCOLOR® Fluorescent Pigment Dye

| FA | FD | FE | FF | FG | JM | EM | FK | FG | FM | FL | FN | |

| Chartreuse | √ | √ | √ | √ | √ | √ | √ | √ | ||||

| Yellow | √ | √ | √ | √ | √ | |||||||

| Green | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Orange-Yellow | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Orange | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Orange-Red | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Red | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Cerise | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Pink | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Magenta | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Blue | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Purple | √ | √ | √ | √ | √ | √ | √ | √ |

BXColor Fluorescent Pigment Dye Series

BXColor Fluorescent Pigment Dye Series