PFAS Free PPA S200

PPA Introduction

Polymer Processing Aids are free-flowing additives made of modified fluoro-elastomer which improve the processing of polyolefin resin at very low levels of usage. BX Polymer Processing Aids are coated at the inside of the die wall and decrease the friction between melted resin and the die wall.

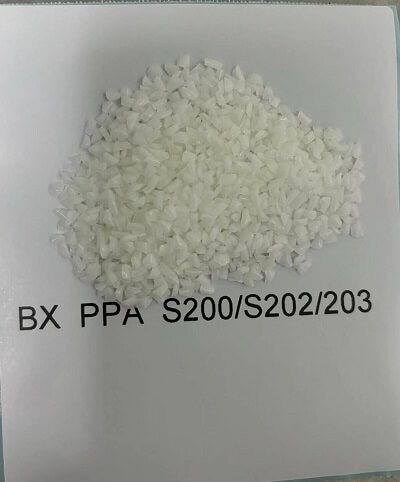

BX PPA S200

BX PPA S200 is a silicone additive containing polar functional groups. It is used in plastic and rubber products such as PE and PP. It can significantly improve processing and demoulding properties, reduce die accumulation and improve melt rupture problems, making the products more durable. Better restoration. At the same time, S200 has a special structure, good compatibility with the matrix resin, no precipitation, and no impact on the appearance and surface treatment of the product.

BX PPA S200 is the latest PFAS Free PPAs, without fluoropolymers.(Click to learn PFAS).

BX PPA S200 Specifications

Physical properties:

Active ingredient (%) 100

Melting point (℃) 45~65

Volatile matter (%) ≤0.5

Appearance (25℃) White or light yellow powde

Introduction

BX PPA S200 can improve the surface properties of the product: improve scratch resistance and wear resistance, reduce the surface friction coefficient, and improve surface smoothness; in terms of polymer processing performance: effectively reduce the torque and current during processing, and reduces energy consumption. At the same time, the product has good mold release and lubricity, improving processing efficiency.

Application

(1)Film

(2)pipe

(3)wire

Dosage

S200 can be premixed with masterbatch, powder, etc., or added in proportion to produce masterbatch. It has high temperature resistance and can be used as additive for polyolefins and engineering plastics. The recommended dosage is 0.1%~5%. The exact amount used depends on the composition of the polymer formulation.

Benefits

– Improve film surface quality by eliminating melt fracture.

– Shorten downtime by reducing die build-up.

– Improve pigment dispersion.

– Increase output and energy saving.

– Improve processability of Low MI resins.

Shelf life:

2 years, below 30℃, avoid extensive humidity and light

Package:

Net 25kg, per carton

TDS/ MSDS

Sample and Inquiry

Please contact our online sales or mail at info@additivesforpolymer.com for a sample and general inquiries.