How To Choose Organic Pigments for Plastic?

(A buyer’s selection guide of organic pigment)

How to choose Pigment Orange for Plastic?

[table id=67 /]

There are nine orange pigments suited for plastics, key features of these plastic orange pigments as below

Pigment Orange 64 is With high tinting strength, high hiding power, high saturation, good dispersibility, good properties, comply with food contact.

Pigment Orange 71 is with better transparency, high saturation, P.O.71 shows better transparency than pigment orange 64.

Pigment Orange 72 is with high tinting strength and high saturation, P.O.72 is more yellow and higher saturation compared with pigment orange 64.

Pigment Orange 61 is with mid weather fastness, best light fastness also higher price among orange pigments. P.O.61 exhibits good weather fastness while lower saturation than pigment orange 72.

Pigment Orange 73 is with high tinting strength, high saturation, poor heat resistance/tinting strength in the low concentration; its crystal will mix when used together with pigment red 254. P.O.73 shows better saturation and pure full shade, redder when comparing with pigment orange 64.

Pigment Orange 68 key features are the reddest shade, best heat resistance while low saturation, suited for nylon.

Pigment Orange 43 is of high saturation, high price, excellent lightfastness in low concentration.

Pigment Orange 13 is of most economic choice, poor light fastness, poor immigration resistance, process temperature shall below 200℃.

Pigment Orange 34 is an economic choice which processing temperature shall below 200℃.

all these nine plastic orange pigment technical positions as below

Here we set pigment orange 64 as the standard orange pigment, there is still space in price down with industrialization and potential market share after that. Start from pigment orange 64, if the user needs higher weather fastness, pigment orange 71 and pigment orange 72 is optional. Also, pigment orange 61 with excellent weather fastness both in full and reduction. Pigment orange 34 is extremely bright while limited market share due to high price pigment orange 73 is beating by pigment orange 64 in the market.To save cost, there are pigment orange 13 and pigment orange 34. pigment orange 34 has better properties than pigment orange 13 and redder. PO34 is of low saturation.

How To Choose Pigment Red For Plastic?

How to choose blue shade pigment red for plastic?

Red and yellow are the two big color families of organic pigments. Commercial available organic red pigments for plastic as the chart below, please click on the hyperlink to go to the product page.

[table id=69 /]

There are 11 blue shade red pigments suited for plastics, key features of these plastic orange pigments as below

Pigment Red 122 has high tinting strength, good fastness properties, bright color after reduction, comply with food contact, also the price is economic nowadays.

Pigment Red 202 shows better properties compared with pigment red 122 and PR 202 is bluer and darker.

Pigment Violet 19 γ form features are mid tinting strength, good properties, comply with food contact, it looks more yellow than pigment red 122.

Pigment Red 179 exhibits mid tinting strength and mid saturation.

Pigment Red 264 is of high tinting strength and transparent color, P.R.264 is more transparent than pigment red 122.

Pigment Red 177 is of High tinting strength, high-transparent, Mid weather fastness.

Pigment Red 185 is of good light fastness and mostly suited for leather, it belongs to middle properties and middle price.

Pigment Red 176 is of good light properties and mostly used for EVA.

Pigment Red 57:1 is a most economic choice.

Pigment Red 48:2 is of most economic choice, meanwhile it’s heat resistance, light fastness goes down.

Pigment Red 170 F5RK is of high tinting strength, good saturation, cost-effective.

all these 11 plastic bluish red pigment technical positions as below

Here we use pigment red 122 as the standard blue shade red pigment, start from here, pigment red 202 is redder and darker, could be used in terylene spinning to solve solubility issue of pigment red 122 in PET. Pigment Red 179 is an option which weather fastness is better while low tinting strength and poor saturation. Pigment Violet 19 γ form, though in same chemistry group, it is yellower than PR122, while tinting strength lower and price higher than PR122. Pigment Violet 19 is much better when toning light color. Pigment Red 264 is DPP pigment, the color shade is close to mid red shade. High in price, good transparency, high tinting strength, good weather fastness is three features. Pigment red 177 has extremely good transparency, exhibit bright color when using in PET/PP fiber. Pigment red 176 often used in getting pink color in EVA. Pigment Red 185 is massively used in leather, like automotive interior.

To save costs, pigment red 170 f5rk is the choice, while user shall know its heat resistance, immigration resistance, weather fastness goes downs. Pigment red 48:2 and pigment red 57:1 is the most economic red.pigment red 48:2 suited for PP spun dyeing, widely used in carpet. User shall mind the color changing issue between high and low temperature.

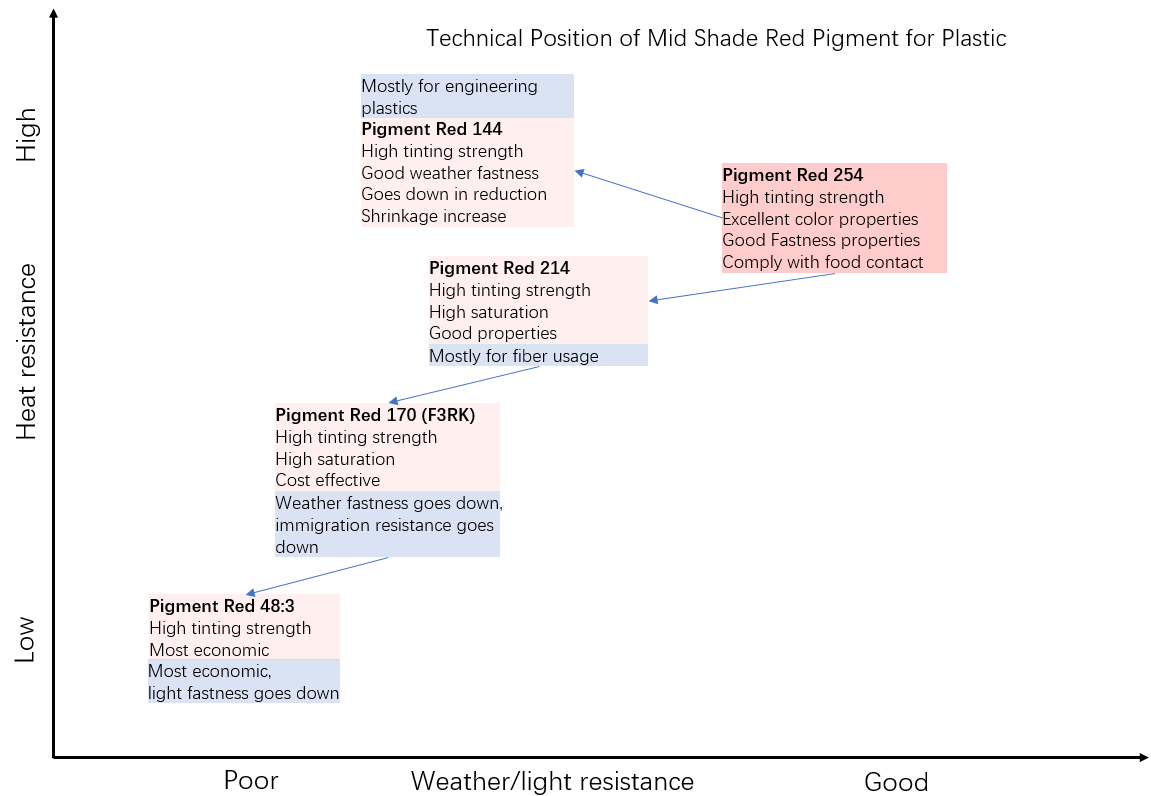

How to choose mid shade pigment red for plastic?

There are 5 middle shade red pigments suited for plastics, key features of these plastic red pigments as below; please click on the hyperlink to go to the product page.

[table id=70 /]

Pigment Red 254 is of high tinting strength, excellent color properties, good Fastness properties, also comply with food contact.

Pigment Red 144 is of high tinting strength, good weather fastness and goes down in reduction, shrinkage increase, PR 144 is mostly used for engineering plastics.

Pigment Red 214 is of high tinting strength, high saturation, good properties, mostly for fiber usage.

Pigment Red 170 (F3RK) is of high tinting strength, high saturation, cost-effective, PR 170 weather fastness goes down, immigration resistance goes down compared with pigment red 214.

Pigment Red 48:3 is of high tinting strength, most economic choice, light fastness goes down when compared with pigment red 170 F3RK.

all these 5 plastic middle shade red pigment technical positions as below

Here we use pigment red 254 as the standard mid shade red pigment; there are 3 grade commercial pigment red 254 available in the market, the small particle size exhibits excellent transparency, the one of big particle size has excellent weather fastness and is taking market share of PR144, PR214, PR170 F3RK. Pigment Red 144 is now used as a complement of PR254 and used in engineering plastics of ABS, PET, PC. Pigment Red 214 is used as a complement of PR254 and used in fiber. Pigment red 254 tinting strength and immigration resistance are better than pigment red 170 F3RK. To save cost, and compromise in heat resistance and light fastness is acceptable, pigment red 48:3 is the choice.

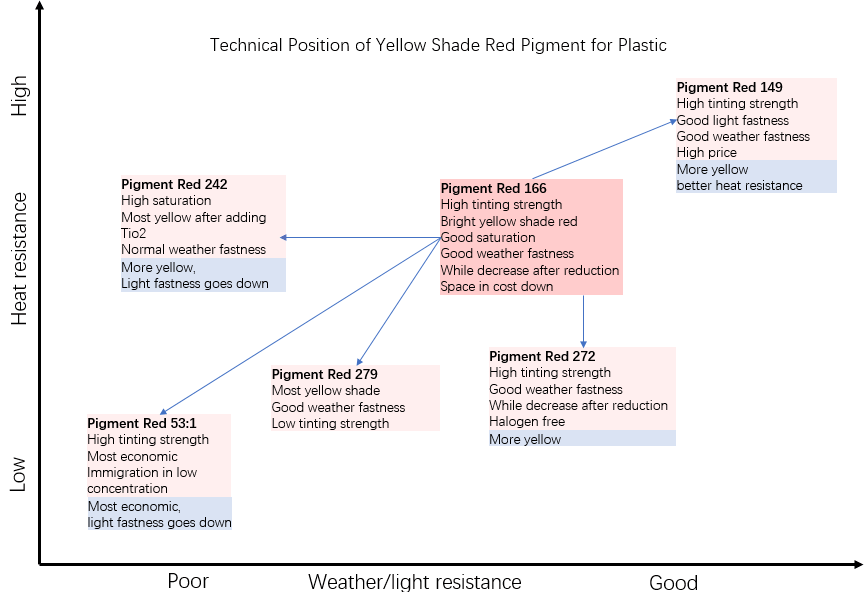

How to choose yellowish pigment red for plastic?

There are total six yellowish red pigments suited for plastics, key features of these plastic red pigments as below,

[table id=79 /]

Pigment Red 166 is of high tinting strength, Bright yellow shade pigment red, Good saturation, Good weather fastness while decrease after reduction, Space in cost down.

Pigment Red 149 is of High tinting strength, Good light fastness, Good weather fastness, High price. PR149 is More yellow, better heat resistance.

Pigment Red 242 is of High saturation, Most yellow after adding Tio2, Normal weather fastness. Compared with pigment red 166, PR242 is More yellow and light fastness goes down.

Pigment Red 272 is of High tinting strength, Good weather fastness, While decrease after reduction, Halogen free.

Pigment Red 279 if of Most yellow shade, Good weather fastness, Low tinting strength.

Pigment Red 53:1 is of High tinting strength, Most economic, Immigration in low concentration.

all these 5 plastic yellow shade red pigment technical positions as below

Here we use pigment red 166 as the standard yellow shade red pigment, start from here, pigment red 272 color shade is close to pigment red 166. PR272 heat resistance is relatively lower while saturation is higher when in low concentration. A bright yellow shade is achieved when pigment red 242 and titanium dioxide mixed, it is the first choice when toning high saturation pink-red. To meet a common requirement combined with cost-effective, pigment red 53:1 is recommended, PR 53:1 light fastness and immigration resistance are poor.

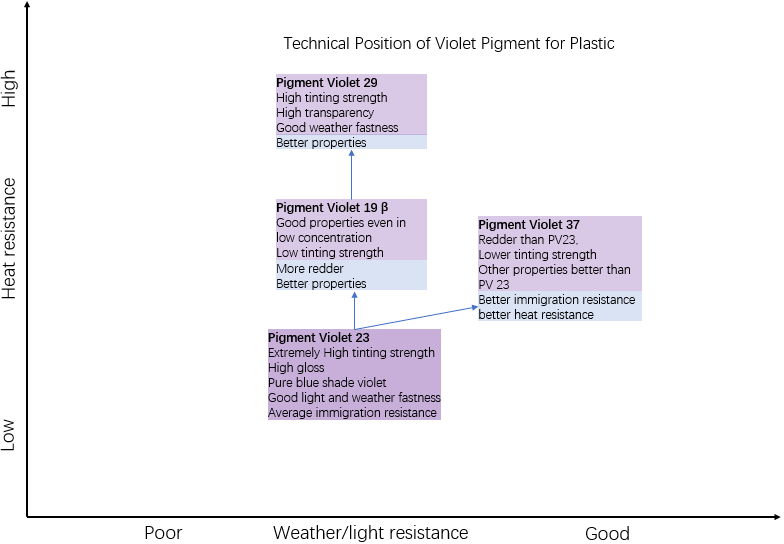

How To Choose Pigment Violet For Plastic?

here are total 4 violet pigments suited for plastics, key features of these plastic violet pigments as below, [table id=80 /]

Pigment Violet 23 is of Extremely High tinting strength, High gloss, Pure blue shade violet, Good light and weather fastness, Average immigration resistance.

Pigment Violet 37 is of Redder than PV23, Lower tinting strength, Other properties better than PV 23, PV37 shows Better immigration resistance, better heat resistance than PV23.

Pigment Violet 19 β is of Good properties even in low concentration, Low tinting strength.it is redder, Better properties.

Pigment Violet 29 is of High tinting strength, High transparency, Good weather fastness.

all these 5 plastic middle shade yellow pigment technical positions as below.

Here we use pigment violet 23 as the standard violet pigment for plastic, with commercial success to make it cost reasonable, it is the first choice of violet pigments. If pigment violet 23 not able to meet user’s requirement in a light color, pigment violet 37 is an option. If user need higher heat resistance and better weather fastness, pigment violet 19 β form is a choice, meanwhile shall pay attention to it‘s low tinting strength, red shade and cost increase. Pigment violet 29 exhibits better all-around properties while price is also higher.

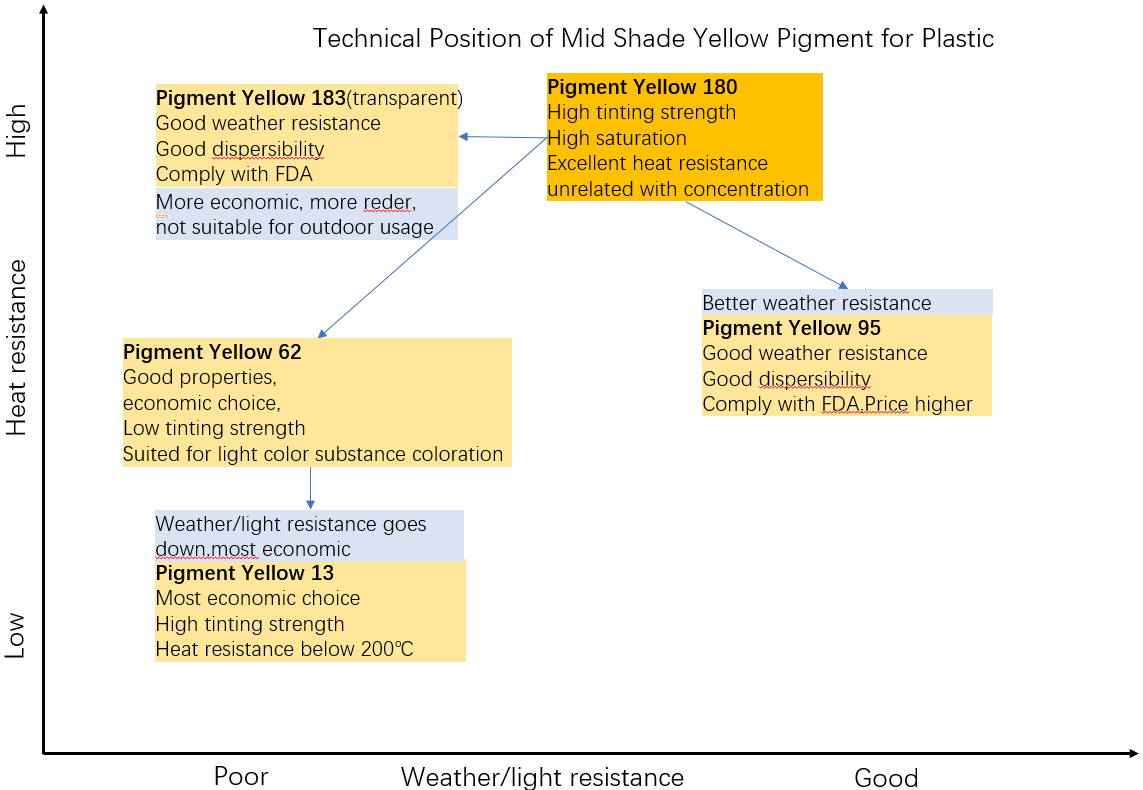

How To Choose Pigment Yellow For Plastic?

How to choose mid-shade pigment yellow for plastic?

There are total 23 organic yellow pigments suited for plastics, key features of these plastic red pigments as below, among them, five are with mid yellow shade, eleven are green shade yellow and seven are red shade. The five mid-shade yellow

pigment key features are as below.

[table id=77 /]

Pigment Yellow 180 is of high tinting strength, High saturation, Excellent heat resistance, unrelated to the concentration.

Pigment Yellow 183 (transparent) is of Good weather resistance, Good dispersibility, also comply with FDA. PY 183 is more economic and redder than pigment yellow 180 while not suitable for outdoor usage.

Pigment Yellow 62 is of good properties, economic choice, low tinting strength, suited for light color substance coloration.

Pigment Yellow 95 is of Good weather resistance, Good dispersibility, comply with FDA, Price is higher and weather resistance is better when comparing with pigment yellow 180.

Pigment Yellow 13 is of most economic choice, high tinting strength, heat resistance below 200℃. Weather and light resistance goes down, most economic in middle shade yellow pigments.

all these 5 plastic middle shade yellow pigment technical position as below

Here we use pigment yellow 180 as the standard mid-shade yellow pigment, start from here, when need higher weather resistance, pigment yellow 95 is an option which color shade is redder. Pigment yellow 62 tinting strength is half of pigment yellow 180, though the price is lower while weak tinting strength offset this cost-effective effect. To save cost, pigment yellow 13 is a choice, PY13 shows the highest tinting strength, economic in price while common heat resistance and light fastness, limited used due to a safety issue.

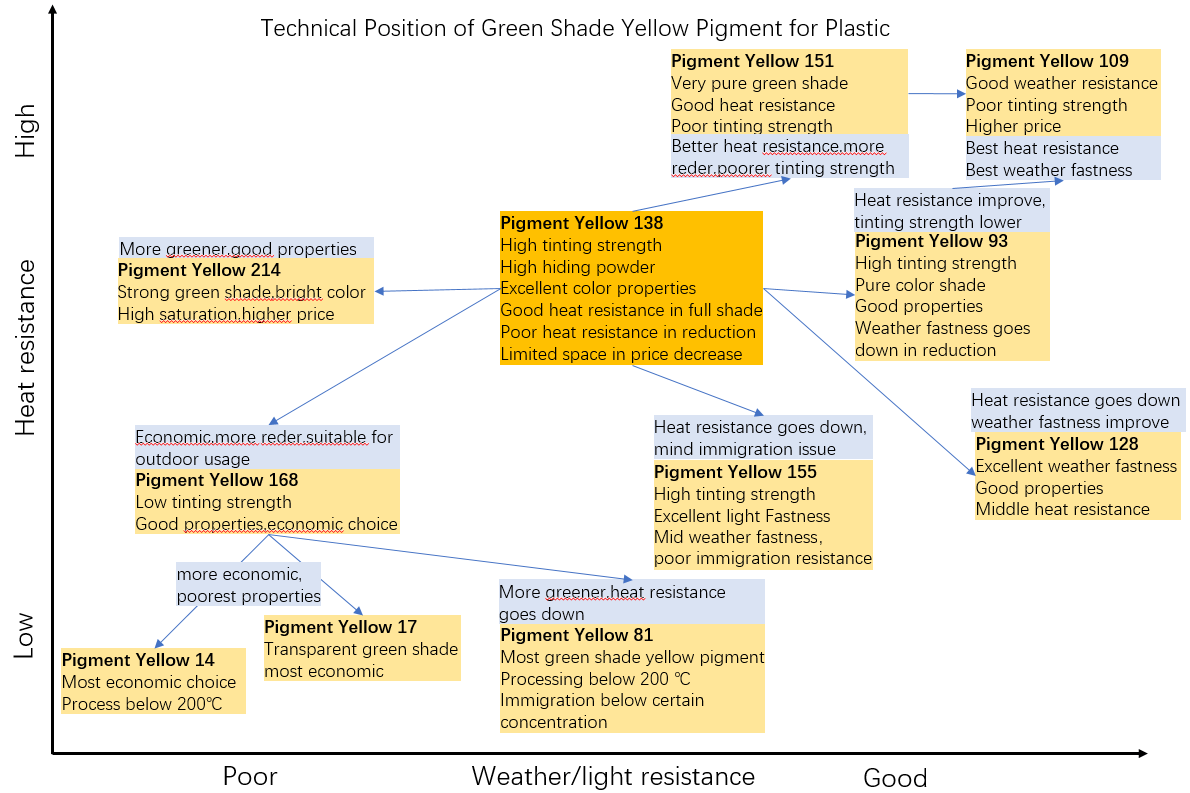

How to choose greenish pigment yellow for plastic?

There are total eleven green shade yellow pigments and key features are as below.

[table id=73 /]

Pigment Yellow 138 is of High tinting strength, High hiding powder, Excellent color properties, Good heat resistance in full shade, while Poor heat resistance in reduction and limited space in the price decrease.

Pigment Yellow 151 is of very pure green shade, Good heat resistance, Poor tinting strength.it shows better heat resistance, more redder, poorer tinting strength compared with pigment yellow 138.

Pigment Yellow 109 is of good weather resistance, Poor tinting strength, Higher price. PY109 exhibits best heat resistance and best weather fastness among these green shade yellow pigments.

Pigment Yellow 93 is of high tinting strength, Pure color shade, Good properties while Weather fastness goes down in reduction. PR 93 heat resistance improves and tinting strength decrease when compared with pigment yellow 138.

Pigment Yellow 214 is of strong green shade, bright color, high saturation, higher price. PY 214 is more greener and better properties than pigment yellow 138.

Pigment Yellow 168 is of low tinting strength, good properties, economic choice. redder than pigment yellow 138 and suitable for outdoor usage.

Pigment Yellow 155 is of high tinting strength, excellent light Fastness, Mid weather fastness, poor immigration resistance. PY155 heat resistance goes down when compared with PY138, what’s more, the user shall pay attention to the immigration issue when using it.

Pigment Yellow 128 is of excellent weather fastness, good properties and middle range heat resistance.compared with pigment yellow 138, PY 128 heat resistance goes down while weather fastness improve.

For more economic, while poor properties choices, there are pigment yellow 14 and pigment yellow 17.

Pigment Yellow 14 is of most economic choice and shall process below 200℃.

Pigment Yellow 17 is of transparent green shade, most economic green shade yellow pigment for plastic.

Pigment Yellow 81 is of most green shade yellow pigment, processing below 200 ℃, PY 81 immigrate below a certain concentration, PY 81 is greener and heat resistance goes down from pigment yellow 168.

all these 11 plastic green shade yellow pigment technical position as below

Here we use pigment yellow 138 as the standard green shade yellow pigment, start from here. When better weather fastness is needed, pigment yellow 128, pigment yellow 93, pigment yellow 151, pigment yellow 109, PY109 is primary, pigment yellow 128 ranks second and mind the heat resistance, pigment yellow 93 is fine, also mind color shade is red. PY151’s heat resistance and weather fastness are better while tinting strength is lower. To save cost, pigment yellow 155 is an option, the user shall mind the immigration issue when using it. To further save cost, pigment yellow 168 is a wise choice, also pigment yellow 17 pigment yellow 14, pigment yellow 81, these are the most cost-effective. User shall mind the Dichloro benzidine safety issue, process temperature below 200℃, what’s more, immigration issue of pigment yellow 14 is an issue.

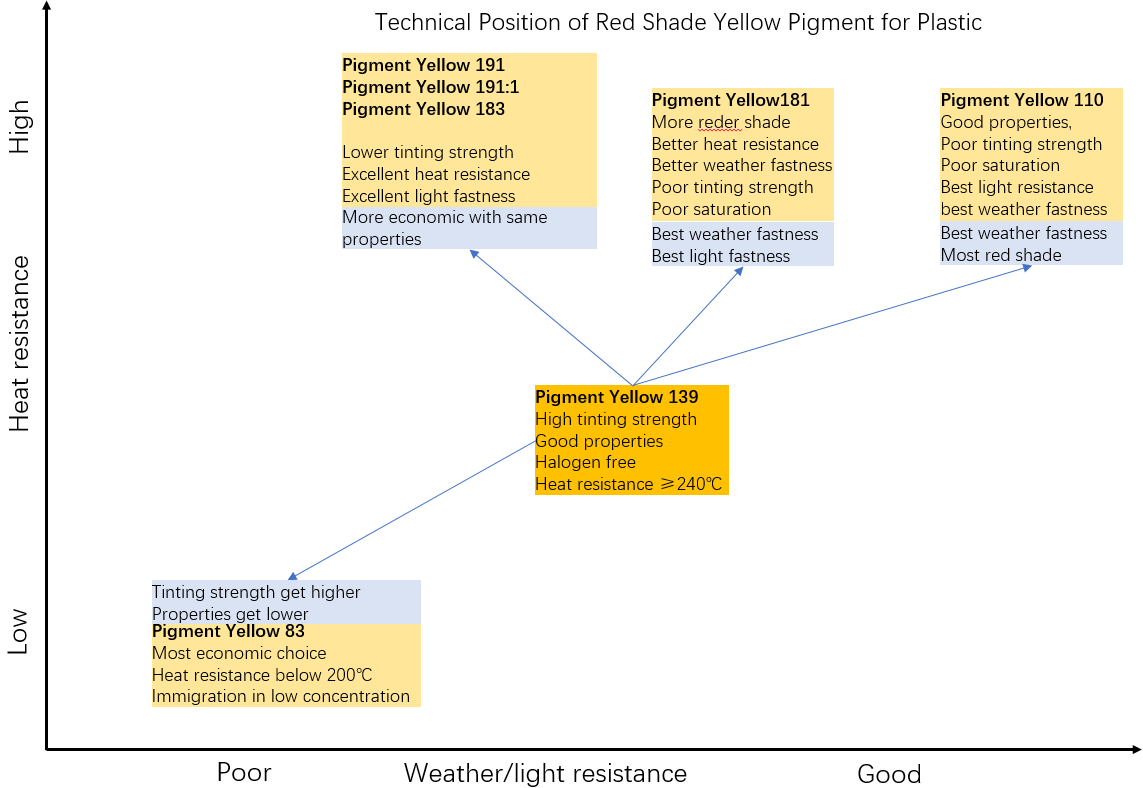

How to choose reddish pigment yellow for plastic?

There are total 7 red shade yellow pigments and key features are as below.

[table id=74 /]

Pigment Yellow 139 is of high tinting strength, good properties,halogen-free, heat resistance ≥240℃

Pigment Yellow 191, Pigment Yellow 191:1 and pigment yellow 183 shows lower tinting strength, excellent heat resistance, excellent lightfastness. These three are more economic with the same properties.

Pigment Yellow 110 is of good properties, Poor tinting strength, Poor saturation, Best light resistance, best weather fastness and most red shade pigment yellow.

Pigment Yellow 83 is of most economic choice, heat resistance below 200℃, Immigration in low concentration. comparing with pigment yellow 139, PY 83 tinting strength get higher and properties get lower.

all these 7 plastic red shade yellow pigment technical positions as below

Here we use pigment yellow 139 as the standard red shade yellow pigment, start from here, there are various pigment in red shade yellow pigment zone. If user need high heat resistance and better weather fastness, pigment yellow 181 is an option which excellent heat resistance in low concentration. PY181 exhibit low tinting strength and high in price, low saturation after reduction. Pigment yellow 110 is redder, better heat resistance and weather fastness, even lower in saturation. To save cost, there are pigment yellow 191 and pigment yellow 183 which both are poor water resistance, PR183 water resistance is better than PR191 while PR191 heat resistance is better than PR183. Pigment yellow 83 is of high tinting strength, good saturation and fine heat resistance, it is the first choice to save costs, the user shall mind the safety issue of Dichloro benzidine when choosing.

How To Choose Pigment Blue For Plastic?

There are four blue pigments for plastics, and key features are as below.

[table id=78 /]

Pigment Blue 15:1 is of high tinting strength, pure red shade pigment blue, high light and heat resistance.

Pigment Blue 15:3 is of high tinting strength, pure green shade pigment blue, high light and heat resistance.

Pigment Blue 15:0 is of high tinting strength, pure red shade pigment blue, good light and immigration resistance, heat resistance 200℃. Due to PB 15 is a not stable crystal structure and heat resistance goes down.

Pigment Blue 60 is of pure red shade pigment blue, good properties, suited for nylon, excellent weather resistance. Redder & better weather resistance than pigment blue 15:1.

all these 4 plastic blue pigment technical position as below

Here we use pigment blue 15:1 as the standard blue pigment, the commercial production makes it’s price acceptable. Pigment Blue 15:3 is β form and stable than pigment blue 15:1, thus, properties is also better. It is widely used in plastics. When a user can’t achieve brighter red color with red, blue pigment, pigment blue 60 is the option, costs increase as well. Pigment blue 15 is most red among all phthalocyanine pigments, only recommend when common heat resistance, red shade, high tinting strength is needed, for example, EVA forming.